A team of seven engineers. One semester.

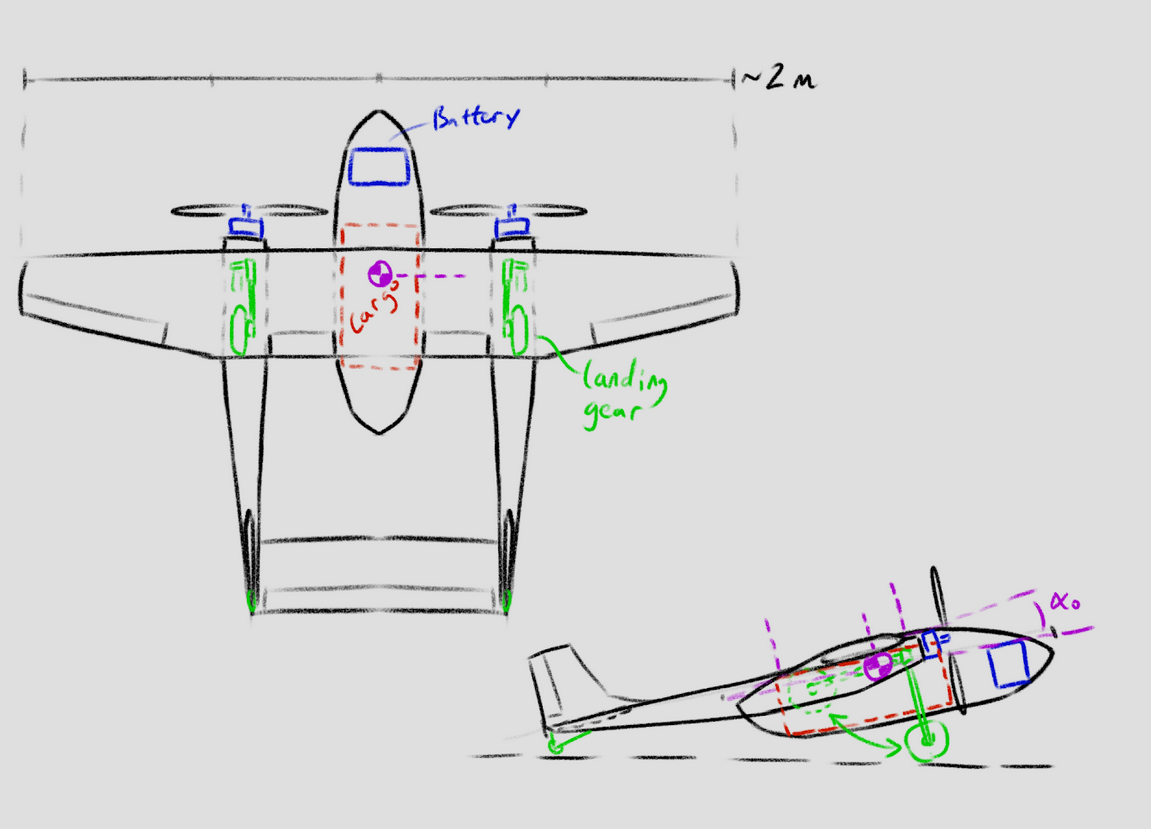

As a senior majoring in mechanical engineering at Duke, I am coming up on my last semester. Consequently, we have been grouped into teams to carry out a semester-long project to demonstrate what we are capable of as graduating engineers. I happen to be the project-initiator for my team: our task is to create an unmanned aerial vehicle (UAV) capable of carrying and deploying a small device from an internal cargo bay. Additionally, we will be designing the aircraft to have very short takeoff and landing capabilities; no VTOL due to the added complexity and aerodynamic inefficiencies (plus, I think there are enough VTOL UAVs out there). All keeping within a very tight budget, to prove that making such an aircraft doesn't require industrial processes.

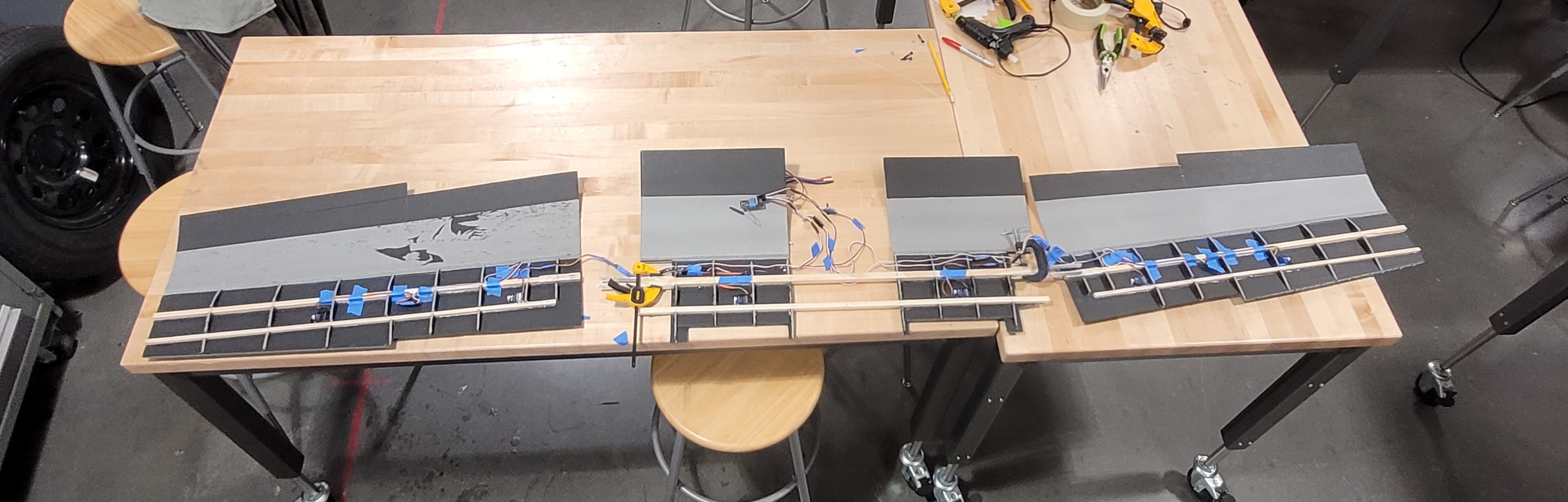

Oh, and the airplane will be made fully from composites, using professional layup techniques. That includes 3D printed molds and vacuum bagging—no foam coring if we can help it. Quite a step up from my discus launch glider, I would say.

I will be leading my team to fully design, manufacture, and fly this aircraft by the end of our senior year, in April-May of 2026.

Team members: Samara Brogan, Sydney Schaffer, Emily Dunn, Ashley Curwin, Miles Bradley, Ethan FernandezCurrently working on: CAD Model

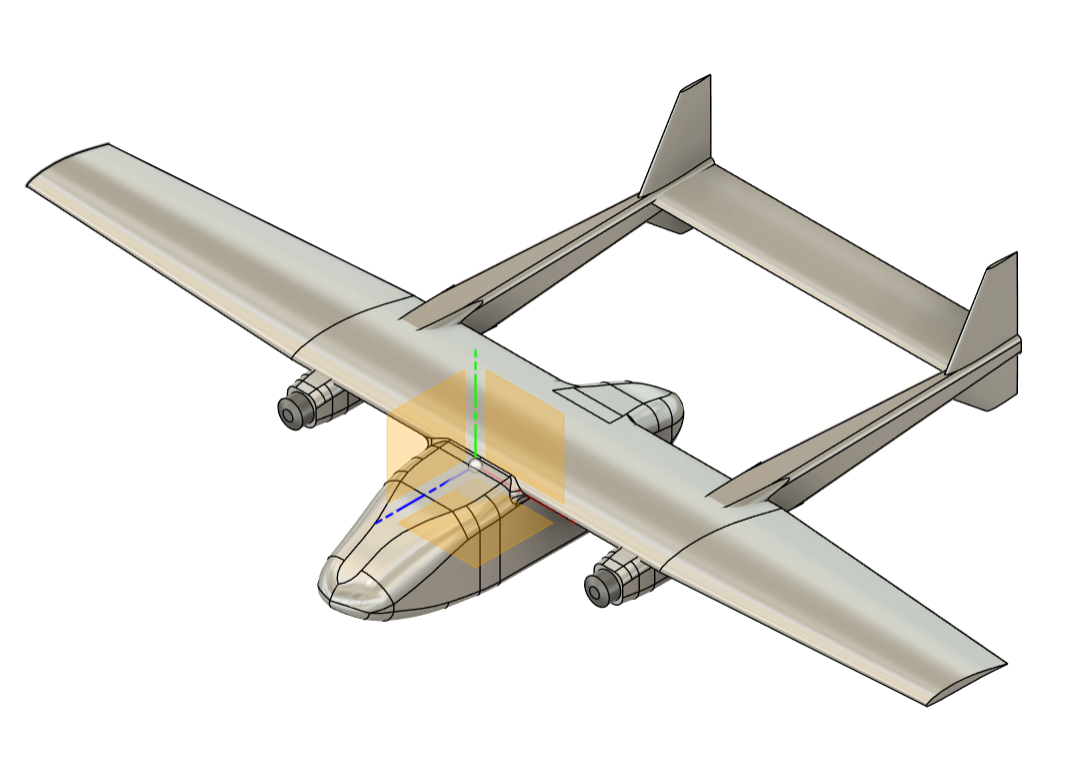

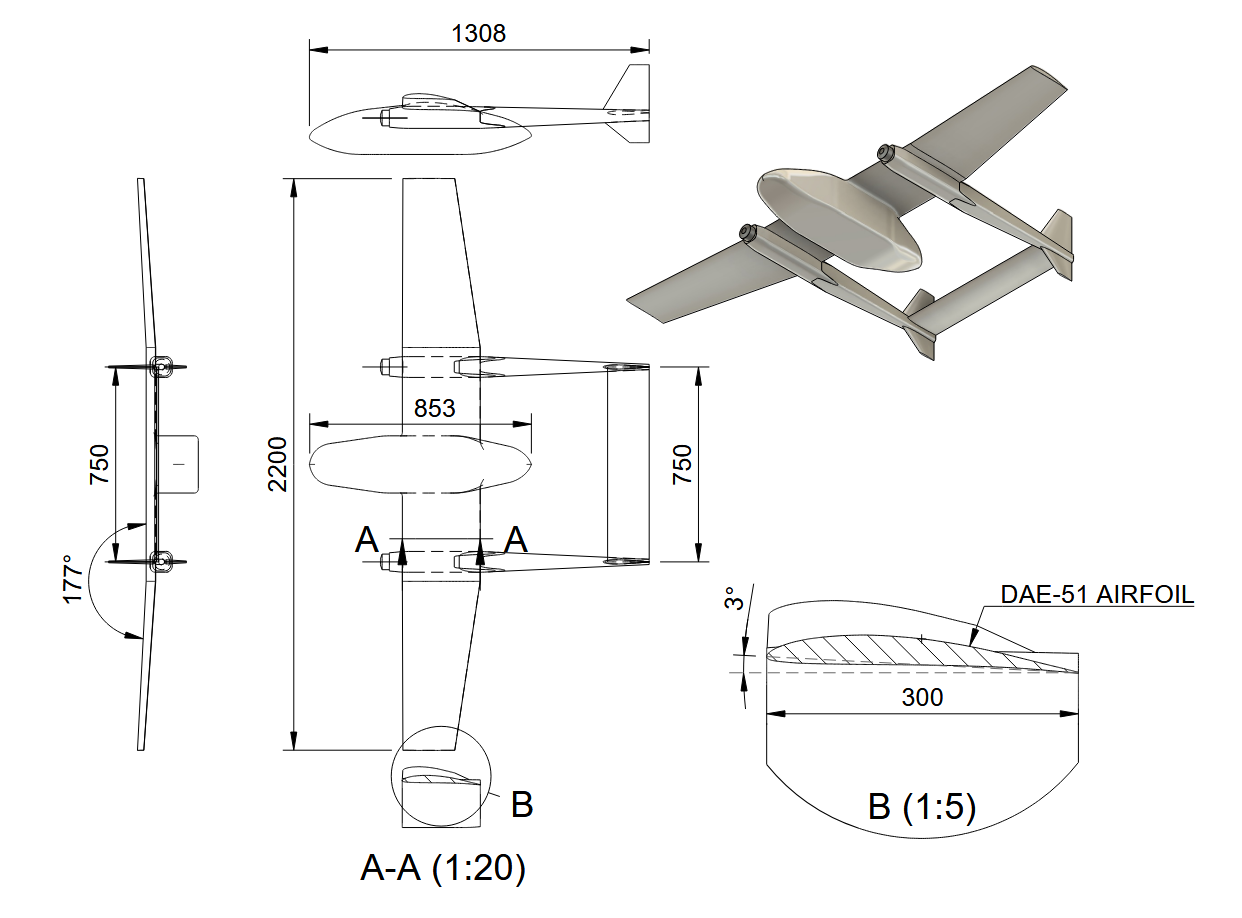

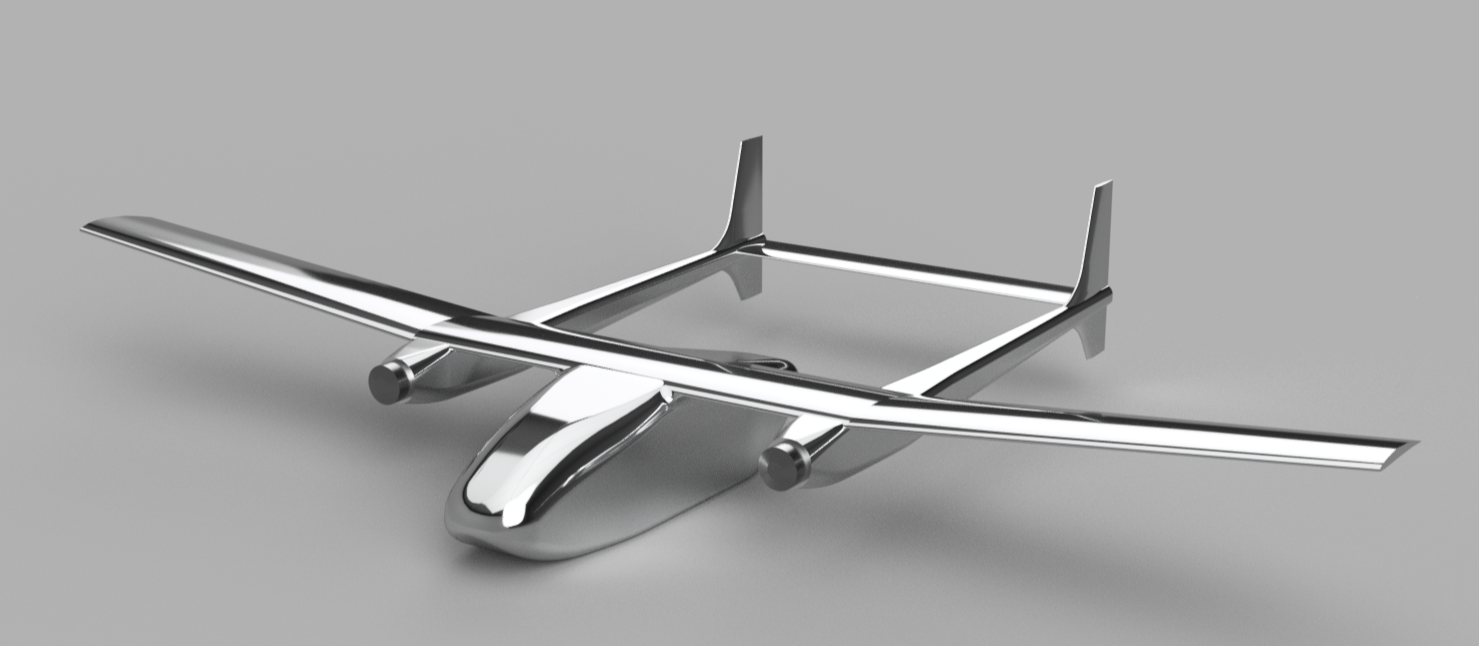

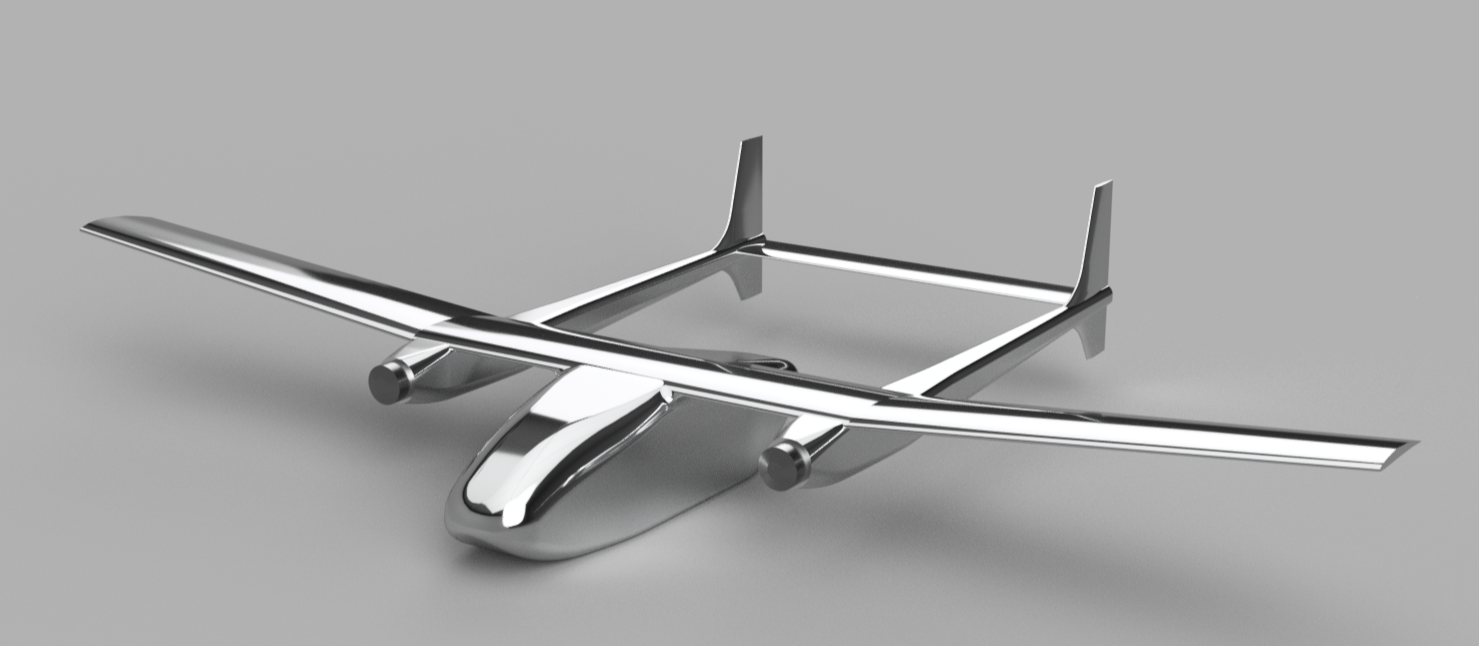

From January 2026: Changes since December: increased aspect ratio of wing (reduced wing chord) for better flight efficiency, and redesigned the fuselage. Pylons are now slimmer and placed closer together, and as a result the length of the extension wings were increased (to retain same wingspan).

Fuselage cargo bay door mechanism.

Fuselage cargo bay door mechanism.

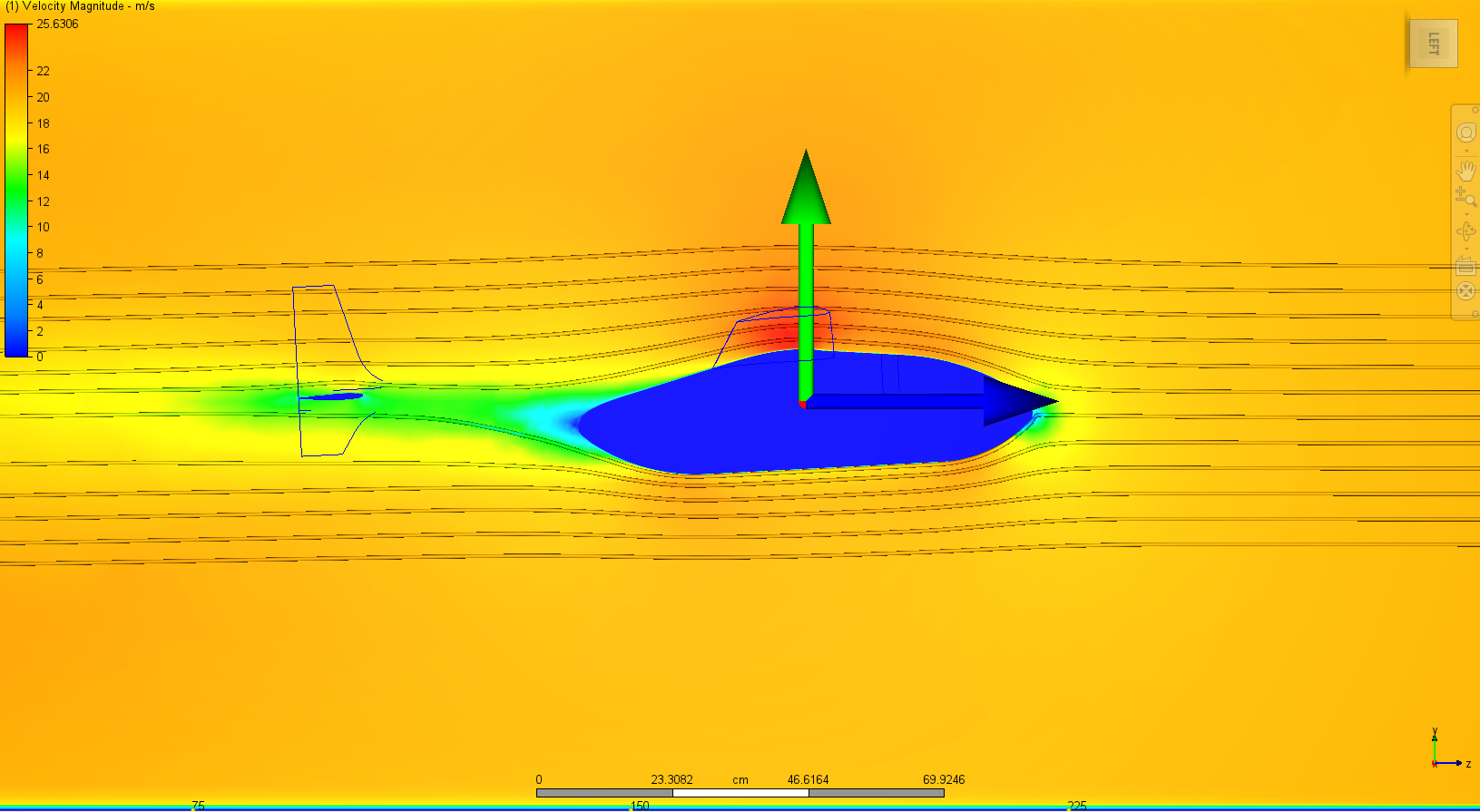

CFD simulation to determine effect of wing wake on horizontal stabilizer.

CFD simulation to determine effect of wing wake on horizontal stabilizer.

From December 2025:

A very preliminary model. The design will likely change quite a bit. To the right: units are in millimeters.