Brief Background:

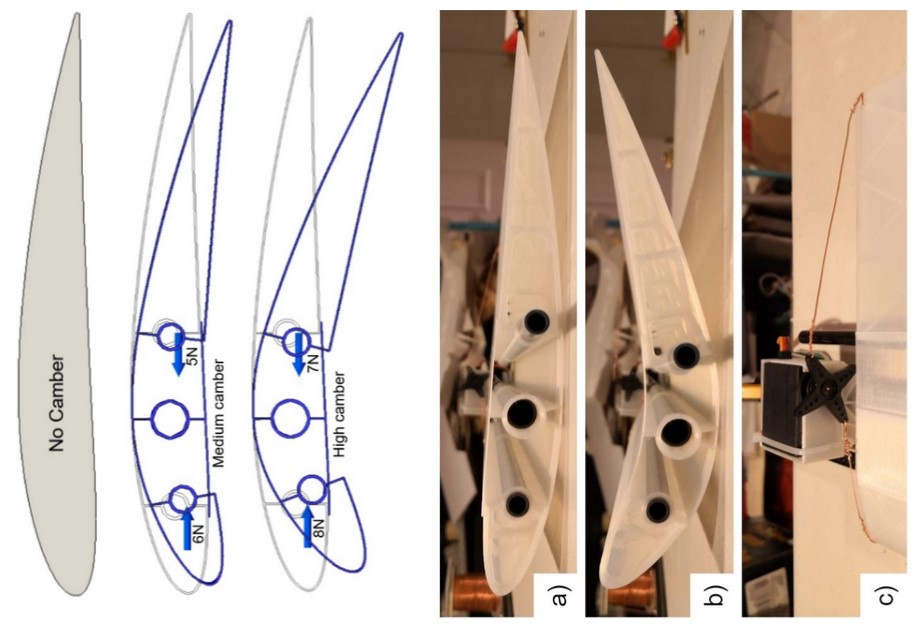

I spent 3 years in highschool doing independent research, mostly focusing the application of 3D printing in aviation. This was mostly inspired by the works of 3DLabPrint, as I was fascinated with the idea of flying a 3D printed RC airplane. This was when I learned most of what I know about aeronautics today, in addition to the various computational tools associated with the research. In 12th grade I presented my paper about compliant variable-camber wings to the Regeneron Science Talent Search research competition, and placed in the top 300 semifinalists in the US!

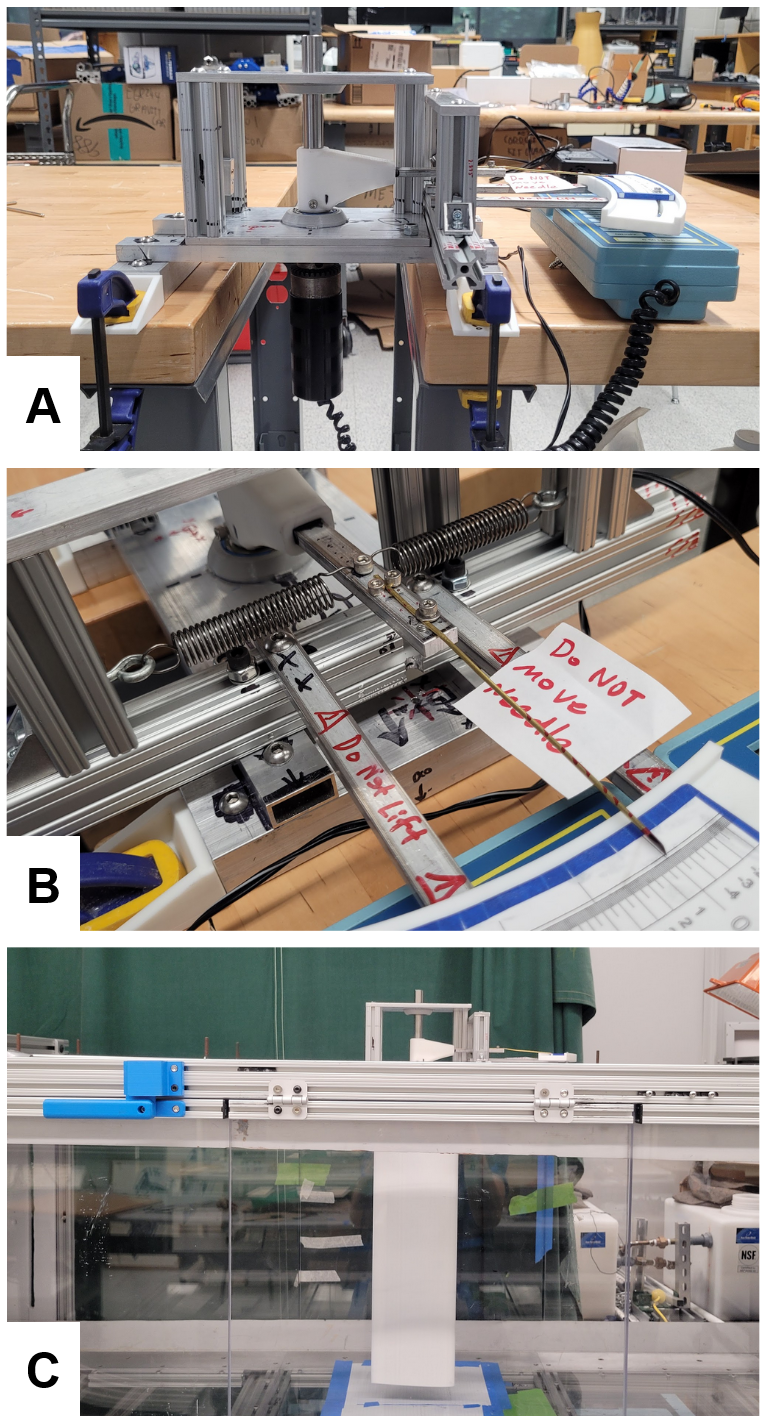

After enrolling in university, I took up research with the Duke Aerolasticity Team, under supervision of Dr. Luisa Serafim and Earl Dowell. I was tasked to collect windtunnel pressure data for an airfoil section under "nonlinear" conditions. This meant studying the airflow as the wing changed its angle of attack, as air has elastic properties and doesn't immediately change in-phase with surrounding objects.

Since March of 2025, I have been working with a fellow undergraduate to study the effects of aeroelastic divergence- a phenomenon where a wing suffers from structural (torsional) instability at a certain critical speed due to an aerodynamic twisting moment. The research paper has recently been submitted to AIAA for review!

Being able to study and conduct both methods of obtaining aerodynamic data (CFD and windtunnel) has vastly expanded my view in aeronautics, as this is what aerospace engineers use in the real world. It is an honor to be able to work with such a talented team on novel research projects, and I hope to continue my involvement in aerodynamic research.

List of past research papers (page redirects)